About Us | Big Bag Technique

At Big Bag Technique, we are known for providing high-quality FIBC discharging and filling machines, along with ancillary equipment, primarily to the OEM market. Our designs are based on over 30 years of experience in the powder handling industry and an in-depth understanding of modern manufacturing practices.

Expertise in FIBC Discharging and Filling Solutions

With decades of expertise in designing, manufacturing, installing, and commissioning powder handling systems, we have developed a wide range of innovative equipment to meet today’s industry standards. Our commitment is to deliver solutions that are:

- Simple and cost-effective to manufacture.

- Robust, reliable, and ensure efficient operation.

- Designed for easy cleaning and low-maintenance.

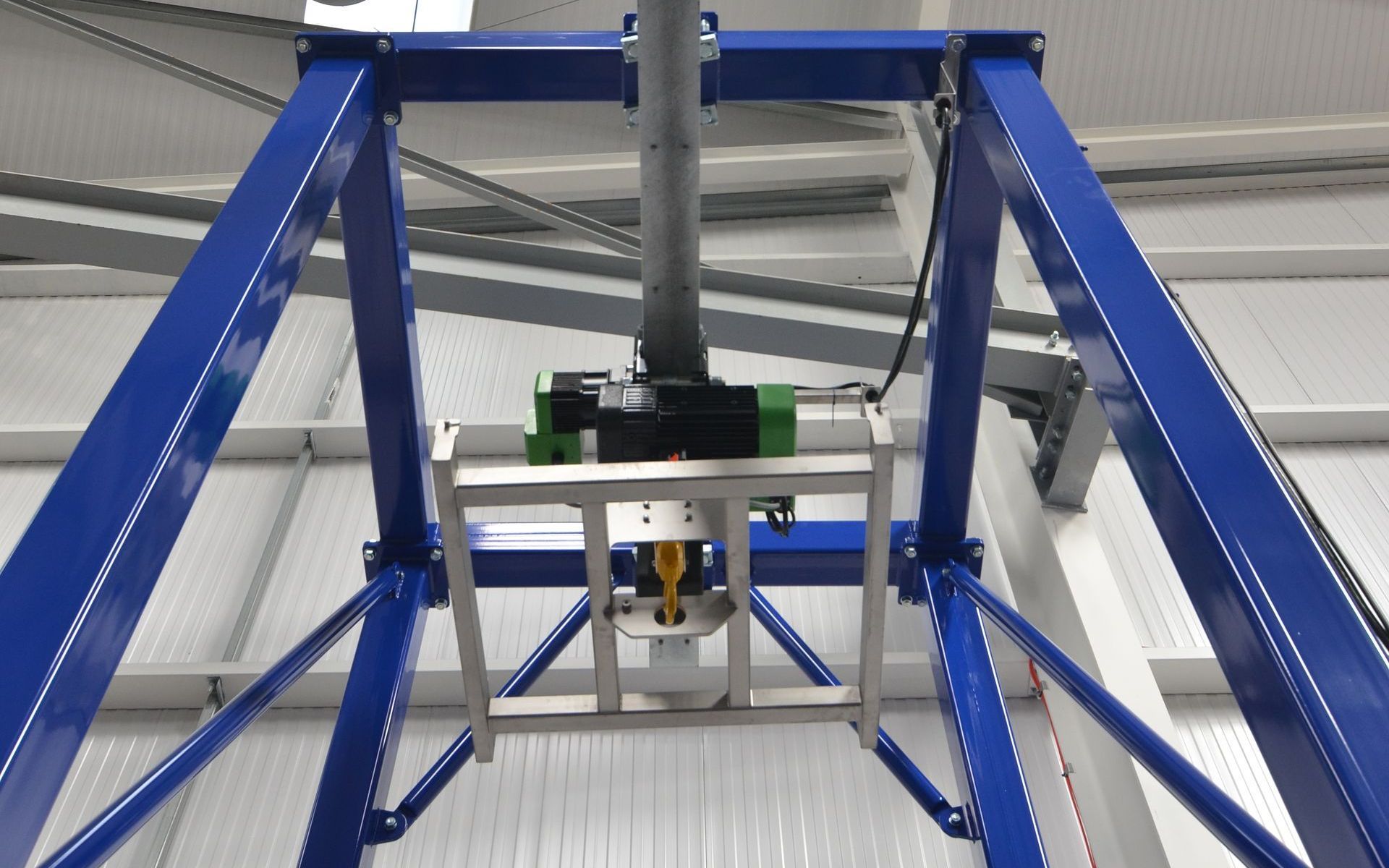

CAD/CAM-Designed Equipment for Precision

Our full range of FIBC discharging and filling systems is designed and manufactured using the latest CAD/CAM technology, allowing us to provide clients with detailed 3D models of their systems. This helps you visualize the final product and ensures smooth integration with existing equipment.

Value Engineered Solutions

We ensure our equipment is value-engineered, using the most cost-effective materials and components. We also offer flexibility by working with client-preferred suppliers and providing expert advice on vibrator motors, hoists, and other components.

Stress-Analysed Gantry and Structural Designs

Our gantries and structural designs are stress-analysed early in the project to ensure optimal strength and durability. This helps streamline the design process and ensures compliance with safety and operational standards.

Collaborative Approach

By working closely with clients from the early design stages, we make the FIBC handling process easy to understand. Close collaboration with both you and your client ensures any concerns are addressed early, building shared confidence in the final product.

Trusted by Major UK Manufacturers

Our reputation is built on attention to detail at every stage of the process— from the initial quotation to manufacturing, installation, and commissioning. We also offer fast, effective on-site support to quickly resolve any issues that arise.