Vibrating Hoppers

A Vibrating Hopper is the simplest method of discharging most products from a big bag (FIBC) in a clean and safe manner. Granular and powdered products will generally react to vibration, which promotes flow from the FIBC outlet spout and then molds the bottom of the big bag into the conical shape of the discharger hopper.

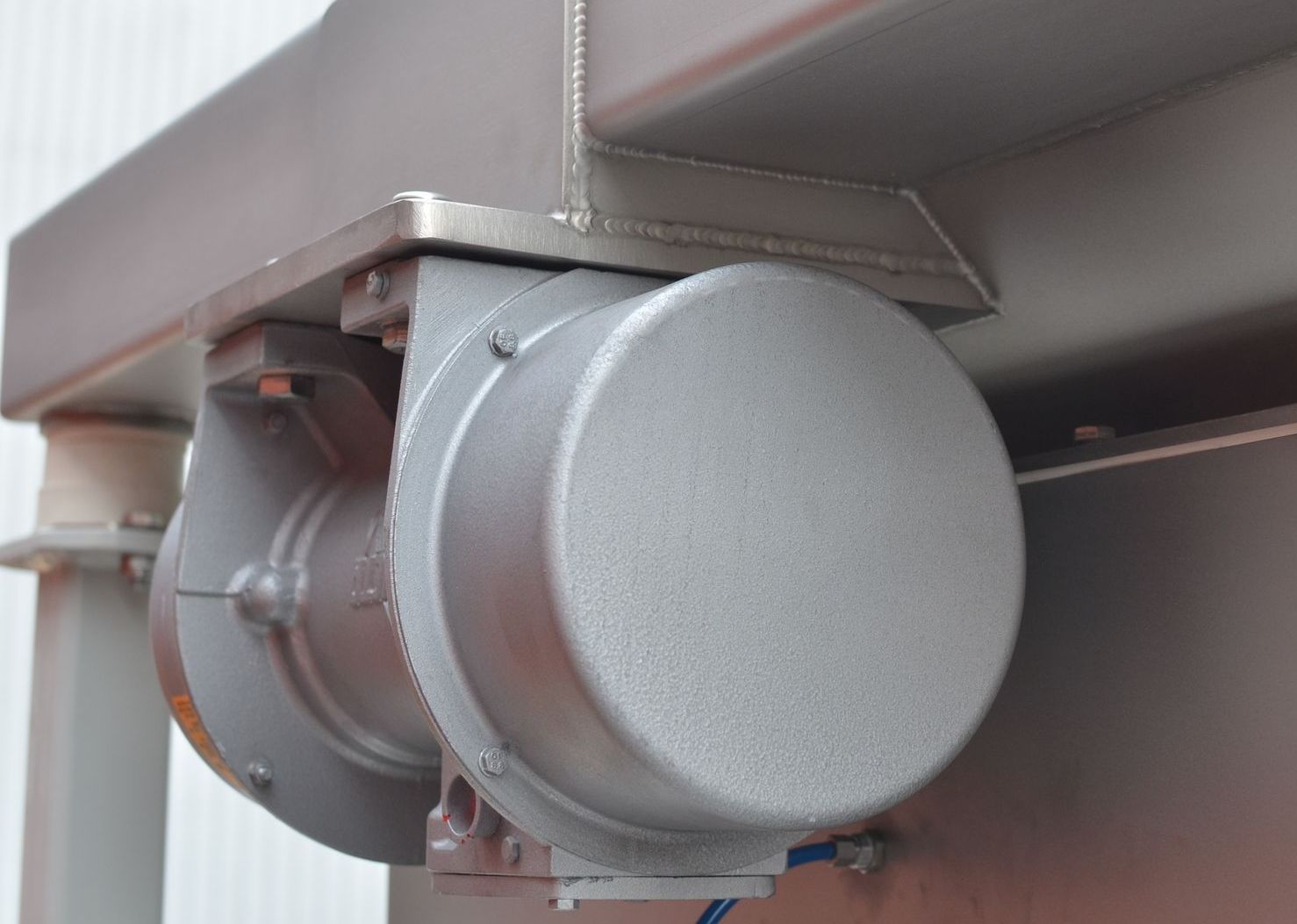

Low cost and low maintenance, vibrator motors agitate product within the FIBC generating flow. The level of vibration easily varied by adjusting out-of-balance weights.

Food grade anti-vibration mounts isolate the hopper from supporting frame or gantry.

Interlocked access door prevents operator reaching moving components in downstream equipment.

Smooth internal and external design simplifies cleaning and minimises cross contamination.